Certified Six Sigma Green Belt

SKF-JRS-1211

-

-

(469 Reviews)

- Skills: Learn statistical analysis and DMAIC methodology for better process efficiency.

- Career: Open doors to industries like manufacturing, healthcare, finance, and tech with certified skills. Lead quality projects and boost organizational success.

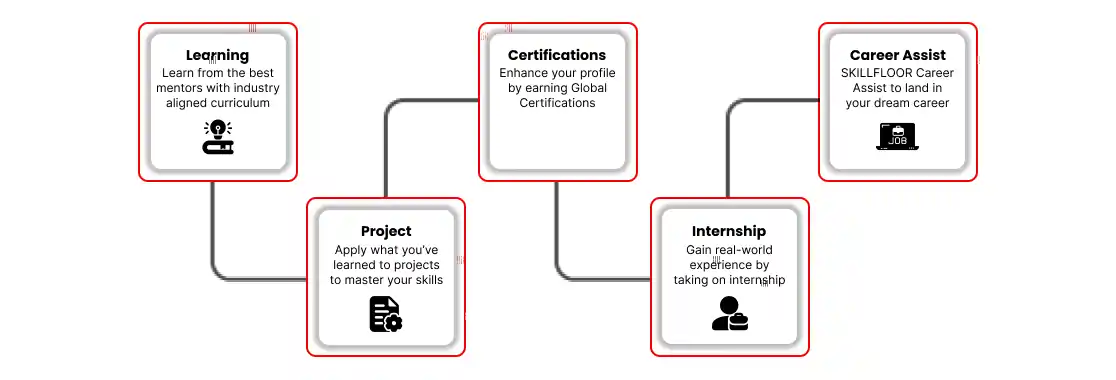

- Internship: Gain hands-on experience with top companies. Apply your Six Sigma knowledge and expand your network while making a real impact.