What is Production System in AI

Learn how production systems in AI work. Understand their rules, inference engines, types like monotonic and dynamic systems, benefits, limitations, and real-world uses in expert systems, chatbots, and automation.

Have you ever interacted with a support bot or asked your phone for assistance? The fact that these products follow exact steps to assist you makes them seem intelligent.

Some systems operate using simple "if this, then that" reasoning, much like a recipe or set of rules for a game. It is dependable, simple to comprehend, and enhances the usefulness of technology in day-to-day living.

For many years, professionals in domains such as healthcare and customer service have relied on rule-based systems to make precise, methodical judgments. Since these technologies don't conceal the decision-making process, they are simple to comprehend. You can see how each step makes sense. This builds trust, particularly when it counts most when assisting someone in making the best decision at the appropriate moment.

What is the Production System in AI?

Electronics frequently address issues or make judgments by following a predetermined set of procedures. They investigate the situation, select a rule that works, and take action rather than speculating. Particularly when we expect straightforward and secure outcomes from ordinary technologies, this makes their behavior more predictable and understandable.

A production system functions similarly to an intelligent checklist. It considers the current circumstance, compares it to a rule, and then abides by that rule. This helps systems in taking the appropriate action at the right time. It is trusted in many fields where thorough consideration is crucial since it is founded on explicit instructions.

Key Components of a Production System in AI

-

Rules (If-Then Statements): These are fundamental directives that direct the system's operations. A specific action is executed if a particular condition is met. It's similar to following detailed instructions.

-

Working Memory: The system keeps up-to-date information here. It monitors current events and updates as circumstances change. This memory is used by the system to determine which rules to adhere to.

-

Knowledge Base: All of the information and regulations are maintained here. It functions as a large manual. This helps the system figure out what is real and what to do.

a. Inference Engine: The engine chooses which rules to apply after determining what is known. It aids in the system's decision-making process. It thinks in both forward and backward directions.

b. Forward Chaining (Data-driven): Begins with well-known facts and works its way through them to arrive at a conclusion.

-

Backward Chaining (Goal-driven): Determines what must be true by starting with a goal and working backwards.

-

Working Memory: As the system operates, facts that change are stored in working memory. Based on current knowledge, it helps choose which rules to apply and maintains track of what is true at any given time.

-

Control Mechanism: The sequence of rule use and system operations is managed by this section. It facilitates seamless operations and provides clear direction for the system from beginning to end, sitting at the Core of AI Concepts.

Types of Production Systems:

-

Monotonic Production System: There is no way to reverse a rule after it has been imposed. The system continues without deleting earlier actions or information. It is constant and never retraces.

-

Non-Monotonic Production System: With this kind, the system might have second thoughts. It can reverse previous actions and update them in light of fresh information. This system is more adaptable than monotone ones.

-

Commutative Production System: Even if the sequence of rule application varies, the system can still arrive at the same conclusion. Steps that may be completed in several ways without affecting the result are useful.

-

Partially Commutative Production System: Rearranging only a few rules are possible. A specific order must be maintained by others. Although it retains control over crucial rule sequences, this type does give considerable freedom.

-

Static Production System: Working memory in this system remains constant while rules are implemented. When just set steps are required and the environment doesn't vary, it's utilized.

-

Dynamic Production System: This system updates its memory while running. It adapts to new facts and responds as situations change making it ideal for real-world uses, where AI impacts are most visible and meaningful.

How Production Systems Work

Production systems use a methodical approach to decision-making and problem-solving. Consider it similar to following a recipe, where each stage is dependent on the previous steps. This is how it operates:

1. Start with Known Facts

The first thing the system does is verify what it already knows. This includes any information or facts that have been provided. Like notes on current events, these data are stored in working memory.

The system gains a good understanding of the present situation due to this first information. This stage, which is crucial to the scope of artificial intelligence, guarantees that all subsequent actions are grounded in current and correct data.

2. Match Rules to the Situation

After the facts are established, the system reviews its set of regulations. It determines which rules apply in the present. Those that fit are the only ones taken into consideration.

Keeping the process intelligent and targeted, helps the system in avoiding arbitrary decisions. It simply considers what is necessary at the time, taking into account the information that is already stored in memory.

3. Resolve Conflicts

Occasionally, more than one rule fits the facts. The best one must then be selected by the system. Resolving conflicts between the matching rules is the term for this procedure.

It chooses a rule based on what makes the most sense at the time. Maintaining a smooth process and preventing misunderstandings about what should happen next depend on this phase.

4. Apply the Rule

The system selects the appropriate rule and then applies it. This entails acting by the regulation or making a memory update.

This is a simple yet crucial step. It is the process by which the system advances and responds to the circumstances, one minor step at a time.

5. Update the Working Memory

Following the completion of the activity, the system changes its memory. In order to represent what has just transpired, it either adds new facts or modifies current ones.

The system can remain aware of any changes thanks to this new memory. It maintains the system's intelligence and responsiveness within the broader context of artificial intelligence applied to practical activities.

6. Repeat the Process

The system restarts with the updated information. It looks for any additional rules that apply to the current circumstance.

Until the objective is achieved or no more regulations are applicable, this cycle of repetition and updating continues. It facilitates the system's ability to manage steps in an orderly and transparent manner.

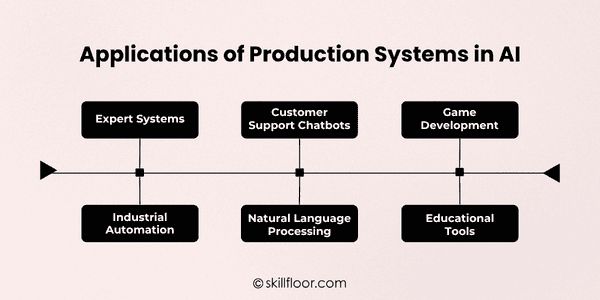

Applications of Production Systems in AI

-

Expert Systems: These systems assist experts, such as engineers or physicians, in making decisions by adhering to explicit guidelines. Similar to seeking advice or assistance from an expert, they provide detailed instructions for resolving issues.

-

Customer Support Chatbots: Chatbots employ rules to respond to your inquiries. They search for the most appropriate rule to fit your question and provide a useful response, just as a competent support representative would.

-

Game Development: Characters make decisions in games by adhering to rules. They may react to the player in clever and enjoyable ways thanks to these principles, which improves the experience and makes it feel livelier and thrilling.

-

Industrial Automation: Rule-based systems help factories run their machinery efficiently. By adhering to a set of rules, each stage helps ensure that things are created correctly, on schedule, and with fewer errors or delays.

-

Natural Language Processing: Systems that deal with language follow word and grammatical standards. This makes communicating with technology feel simpler, more natural, and more beneficial by enabling people to comprehend what is being said and reply appropriately.

-

Educational Tools: Simple guidelines are used by learning applications to verify responses and provide feedback. They provide you the correct instructions if you make a mistake so you may learn and try again with assurance.

Benefits of Production Systems

-

Easy to Understand: Production systems employ simple "if-then" principles that are easy to understand. This facilitates comprehension of the system's operation and capabilities, much like reading detailed instructions.

-

Flexible and Modifiable: The rules may be readily updated or changed without requiring a whole rebuild. The system can easily adjust to changing circumstances thanks to its flexibility, which is helpful when new concepts or modifications arise.

-

Step-by-Step Logic: These systems do things one step at a time to solve issues. Before acting, they verify the facts and decide on a rule. This transparent procedure makes it easier for individuals to understand how and why choices are made.

-

Good for Repeated Tasks: Production systems are useful for tasks that must be completed repeatedly in the same manner. They adhere to the guidelines precisely, which helps with tasks that require precision and reliable outcomes each and every time.

-

Works Well with Expert Knowledge: Rules created by actual experts can be used to construct the system. This implies that others can profit from professional judgment and guidance without requiring the expert's constant presence.

-

Clear and Transparent Decisions: Every action is based on a visible rule. In the world of Artificial Intelligence, this clarity helps people trust the system and understand its logic without confusion or mystery.

Limitations of Production Systems

-

Too Many Rules: Managing a system gets more difficult when it includes hundreds of rules. It takes longer to figure out the best rule, and maintaining organization might become rather difficult.

-

No Learning Ability: Systems in production don't learn by themselves. They have set laws and are incapable of growing with time. They are limited in their ability to be intelligent or adaptable since each new scenario requires a manually implemented rule.

-

Rule Conflicts Occur: Occasionally, many rules apply. This leads to a conflict, and the system has to decide which to use. It might not choose the optimal choice every time, which could result in errors or hold-ups.

-

Needs Expert Input: The system relies on exact regulations. Someone with in-depth expertise of the issue is needed to write these regulations. It's challenging to create a system that functions successfully in practical settings without professional assistance.

-

Slow Rule Updates: Rapid change may cause manufacturing processes to lag. It takes time to add new rules for each update, which hinders the system's capacity to respond quickly to demands or situations that change.

-

Limited Problem Solving: These systems are good at simple tasks but not complex thinking. In some Domains of AI, this makes them less helpful for solving tough problems that need flexibility and creativity.

Production System vs Other AI Systems

|

Aspect |

Production Systems |

Other AI Systems |

|

Decision Making |

Makes decisions using fixed "if-then" rules written by people, following clear steps. |

Learns from data patterns and creates its own way to make decisions over time. |

|

Transparency |

Every decision is easy to trace because all rules are visible and understandable. |

Decisions are harder to explain as the process is hidden inside complex systems. |

|

Learning Ability |

Does not learn by itself. You must manually add or change rules for new behavior. |

Learns automatically from new data and improves without needing new rules manually. |

|

Rule Handling |

Uses only rules written by experts and does not create or adjust rules itself. |

Creates and adjusts its own rules through learning and data training processes. |

|

Flexibility |

Works best in situations where steps are known and don’t change often. |

Can handle changing conditions and new problems that it hasn’t seen before. |

|

Setup Time |

Quick to set up if rules are known; doesn’t need large amounts of data. |

Needs a lot of data and time for training before it works effectively. |

Production systems operate in the background to facilitate the development, comprehension, and trustworthiness of innovative tools. They provide precise procedures that yield dependable outcomes by employing straightforward "if-then" criteria. These systems have shown themselves useful in a variety of contexts, from assisting students and physicians to operating machinery and chatbots. They follow easily verifiable and modifiable logic rather than relying on conjecture. Their strength is that they are simple to manage, update, and explain, even though they might not learn on their own. Production systems remain a reliable option for situations when simplicity, consistency, and clarity are desired.