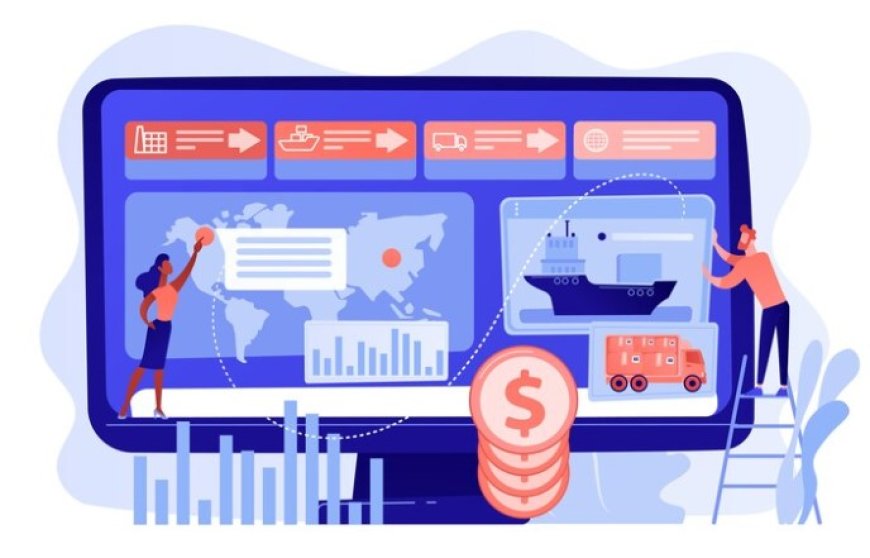

AI in Supply Chain Management: Revolutionizing Logistics and Forecasting

Explore the impact, benefits, and challenges of integrating artificial intelligence into supply chain operations.

The world of supply chain management is undergoing a profound transformation, driven by the integration of Artificial Intelligence (AI). AI's unparalleled capacity to process extensive datasets, learn from patterns, and make predictive decisions is reshaping how companies optimize logistics and forecast demand.

AI in Logistics Optimization:

The infusion of AI into logistics optimization has inaugurated an era of unparalleled efficiency and precision in supply chain management. AI's prowess in handling vast data troves, deciphering patterns, and making data-driven decisions is revolutionizing route optimization, inventory management, and transportation planning. By harnessing AI-powered algorithms that factor in historical data, real-time traffic conditions, and customer preferences, logistics operations are becoming more streamlined. The result is reduced costs, minimized fuel consumption, and a more sustainable supply chain. As AI continually advances logistics optimization, its transformative impact on supply chain management becomes increasingly evident, equipping companies with the tools needed to navigate today's intricate distribution networks with unprecedented accuracy and agility.

Precision Demand Forecasting:

Accurate demand forecasting is pivotal in modern supply chain management, and AI stands out as a potent tool to achieve this precision. Traditional methods often fall short in capturing the complexities of market dynamics. AI revolutionizes demand forecasting by incorporating a wide array of variables, from historical data to real-time market trends and social sentiment. This amalgamation of data empowers AI-powered systems to offer precise and dynamic predictions, enabling companies to optimize production, inventory levels, and resources with greater efficiency. The outcome is a finely-tuned supply chain that minimizes wastage, operational costs, and ensures products are readily available to meet consumer demand. This enhances overall business performance and customer satisfaction.

Minimizing Lead Times and Delays:

Reducing lead times and minimizing delays has always been a perpetual challenge in supply chain management. However, with the incorporation of AI, this challenge is being addressed with unprecedented efficiency. AI's capability to analyze diverse data sources, predict potential disruptions, and offer proactive solutions is revolutionizing how companies manage their supply chains. By providing real-time insights and early warnings, AI empowers businesses to make timely decisions that prevent production slowdowns, maintain consistent delivery schedules, and enhance the reliability and resilience of their supply chain networks. As AI refines its predictive capabilities, the reduction of lead times and delays underscores its transformative potential in ensuring smoother and more efficient supply chain operations.

Empowering Supplier Relationship Management:

AI is revolutionizing supplier relationship management by offering organizations deeper insights into vendor performance and potential risks. Through the analysis of data from various sources, including historical interactions, market trends, and external factors, AI provides a comprehensive view of supplier reliability. This proactive approach strengthens collaboration, negotiation outcomes, and builds a more resilient supply chain network. With AI's ability to identify alternatives in case of emergencies, businesses can navigate disruptions more effectively, ensuring a continuous flow of goods and services throughout the supply chain.

Real-time Tracking and Visibility:

One of the game-changing aspects of integrating AI into supply chain management is its provision of real-time tracking and visibility across the entire supply chain network. By merging the power of Internet of Things (IoT) devices and sensors with AI analytics, companies attain unparalleled transparency into the movement of goods and materials. This level of real-time insight allows for continuous monitoring of shipments, immediate detection of anomalies, and timely decision-making. Ultimately, this heightened visibility enhances security, optimizes operational efficiency, and empowers companies to swiftly respond to any disruptions or changes in the supply chain. This contributes to smoother operations and improved customer experiences.

Challenges and Considerations

While the benefits of AI in supply chain management are substantial, several challenges and considerations must be addressed. These include data quality and integration complexities, privacy and security concerns, change management, algorithm bias, skill gap, complexity and interpretability of AI algorithms, cost and ROI analysis, vendor lock-in, regulatory compliance, and data ownership and collaboration in complex supply chain networks. Careful attention to these aspects is vital for the successful integration of AI in supply chain management.

-

Data Quality and Integration: AI's effectiveness hinges on data quality and accessibility. Organizations must ensure their data is accurate, consistent, and up-to-date. Integrating data from diverse sources can be complex, necessitating data standardization and cleansing efforts.

-

Privacy and Security: Handling sensitive supply chain data demands robust cybersecurity measures to safeguard against data breaches and unauthorized access. Balancing data sharing with privacy concerns is vital, especially when collaborating with partners and suppliers.

-

Change Management: Introducing AI-driven processes often necessitates a cultural shift within organizations. Employees may resist change or feel overwhelmed by the technology. A comprehensive change management strategy is essential to ensure smooth adoption.

-

Algorithm Bias: AI algorithms can inadvertently perpetuate biases present in historical data, resulting in unfair decisions and unintended consequences. Continuous monitoring and adjustment of algorithms are necessary to ensure fairness and equity.

-

Skill Gap: Adopting AI in supply chain management requires a skilled workforce capable of understanding, operating, and maintaining AI systems. Upskilling employees or hiring AI professionals may be necessary to maximize the benefits.

-

Complexity and Interpretability: AI algorithms can be complex and challenging to interpret. Understanding how AI arrives at decisions can be difficult, particularly for non-technical stakeholders. Developing explainable AI models is crucial for transparency.

-

Cost and ROI: Implementing AI solutions involves upfront costs, including technology infrastructure, software development, and training. Organizations must assess the potential return on investment (ROI) to justify these expenses.

-

Vendor Lock-In: Becoming overly reliant on a specific AI vendor can limit flexibility and hinder the ability to switch platforms or technologies in the future. Evaluating vendor relationships is crucial to maintain agility.

-

Regulatory Compliance: The use of AI in supply chain management may be subject to industry-specific regulations and compliance standards. Ensuring that AI practices align with legal requirements is paramount.

-

Data Ownership and Collaboration: In collaborative supply chain networks, data ownership and sharing agreements can become complex. Establishing clear guidelines and agreements for data ownership and usage is essential to avoid conflicts.

Supply Chain Personalization

Supply Chain Personalization is a pivotal aspect of modern supply chain management, whereby operations are customized to cater to individual customer preferences. By embracing AI-driven insights, organizations can enhance customer satisfaction and build loyalty. Furthermore, this approach minimizes excess inventory and reduces wastage, ensuring a more efficient and responsive supply chain system. In essence, personalization not only benefits customers but also optimizes resource allocation and sustainability within the supply chain.

Global Supply Chain Optimization

Global Supply Chain Optimization harnesses the power of Artificial Intelligence (AI) to navigate the complexities of international logistics. AI streamlines the management of cross-border operations by addressing intricate customs and regulatory challenges. Through predictive analytics and real-time decision-making, it ensures efficiency and compliance, enabling businesses to operate seamlessly on a global scale. By leveraging AI's capabilities, companies can achieve a higher level of precision and agility in their international supply chain, ultimately leading to reduced costs and enhanced competitiveness.

Supply Chain Digital Twins

Supply Chain Digital Twins are emerging as a powerful tool in supply chain management, driven by AI technology. They enable organizations to create virtual replicas of their supply chain processes, products, and systems. These digital twins facilitate simulation and analysis, helping identify bottlenecks and inefficiencies within the supply chain. By optimizing operations in this virtual environment, companies can fine-tune their real-world supply chain processes, leading to enhanced efficiency and agility. Digital twins are a key component of AI-driven supply chain transformation, offering a dynamic approach to process optimization and problem-solving.

Blockchain Integration

The integration of blockchain technology with AI in supply chain management is a powerful combination that offers transparency, data integrity, and enhanced security. By combining AI's analytical capabilities with blockchain's immutable ledger, organizations can ensure greater transparency in their supply chain operations. This integration enhances data integrity, enabling the traceability of goods and transactions throughout the supply chain network. As a result, supply chain security and reliability are significantly strengthened, reducing the risk of fraud and errors while fostering trust among stakeholders. This synergy between AI and blockchain represents a pivotal advancement in modern supply chain management.

Consumer Insights and Market Trends

AI plays a pivotal role in analyzing vast troves of consumer data and deciphering dynamic market trends. By harnessing AI's analytical capabilities, organizations can gain deeper insights into consumer behavior and preferences. This enables them to adapt and fine-tune their supply chain strategies in response to ever-changing market dynamics. AI's real-time data processing empowers businesses to stay agile and responsive, ensuring that they meet evolving consumer demands and maintain a competitive edge in the market.

Predictive Maintenance

Predictive maintenance is a critical application of AI within supply chain management. AI plays a pivotal role in forecasting and anticipating equipment maintenance needs, offering significant advantages in terms of reducing downtime and preventing costly breakdowns.

AI's Role in Predicting Equipment Maintenance Needs

AI leverages data from various sources, including real-time equipment performance data, historical maintenance records, sensor data, and even external factors like weather conditions. Through sophisticated algorithms and machine learning models, AI analyzes this data to identify patterns, anomalies, and early signs of equipment wear and tear. By continuously monitoring the condition of machinery and equipment, AI can predict when maintenance will be required with remarkable accuracy.

Reducing Downtime and Preventing Breakdowns

The ability to predict maintenance needs allows organizations to move from reactive maintenance strategies (fixing equipment after it breaks down) to proactive and preventive maintenance approaches. By addressing potential issues before they escalate, companies can significantly reduce unplanned downtime. This not only minimizes disruptions in production and logistics operations but also extends the lifespan of equipment, leading to cost savings in the long run. Furthermore, by preventing unexpected breakdowns, AI-driven predictive maintenance enhances overall supply chain reliability and resilience.

The integration of AI into supply chain management holds immense potential for improving efficiency, accuracy, and resilience in this critical sector. However, organizations must navigate challenges and considerations carefully to fully harness the transformative power of AI while ensuring data security, compliance, and a skilled workforce to thrive in this AI-driven era of supply chain management.